Great job, very clean. Hoping Agile or another vendor will produce a kit so I can be lazy and just bolt it on without out any fabrication steps. I have done lots of fab work in the past but sometimes you just want the easy buttonSo I thought I had better have a go at this since I suggested it way back here.

I used the same universal kit as @landmannnn. Example on Amazon AU here.

View attachment 7918975

This was an exercise in put-up or shut-up to see how much of a PITA it would be to adapt and fit this universal kit. Not too bad, but you're working with 5mm thick steel so allow for that if you contemplate doing something similar with this kit.

Should you do this? Not unless you're the anxious type who worries about a possible driveshaft separation. I did it as an exercise because I have the time and tools. There's been a few driveshaft separations but they're rare enough that you should not lose sleep over it. But as I have said elsewhere, you're trying to avoid secondary damage to the vehicle from a flailing driveshaft if it occurs. This loop does that. It's definitely doable but me doing it as an exercise is not a recommendation that you should also.

Everything I needed was in the kit but I modified it a fair bit so I would call it a donor kit. You get two mount arms and two half-loops plus some Chinesium hardware. I did it slightly different to Landmannn. I chopped up both arms to make one long mount arm to attach to the cross member. The holes in the cross member are on a 260mm spacing so I needed to lengthen one mount arm to pick up the 2nd hole. I used some of the chopped up bits to make a riser to set the loop height I wanted, plus drilled a 2nd set of holes in the half-loops then chopped off the original set to make the half-loops shorter and the loop diameter smaller. The bottom half of the loop is a bit redundant because it extends below the cross member so a flailing driveshaft will be restrained at the bottom by the cross member not the safety loop. But I ended up with a loop that is centred over the driveshaft with good clearance all around to allow for suspension travel. The top half of the loop sits just below the transfer case Bowden cable.

In the words of all dedicated DIYers: "That (driveshaft) ain't going nowhere."

Installation is easy. The mount arm, riser and top half-loop are assembled as one piece. I welded it all together after I got everything in the right place using the bolt holes. I left some bolts in place to fill up the unused holes. Place that piece over the driveshaft then loosely attach the mount arm to the cross member. Install the lower half loop and connect with 4x (upgraded) bolts and nyloc nuts. I slotted the holes in the mount arm so I could centre the loop to the driveshaft. Line that up then tighten the cross member bolts and it's done. Removal is the reverse.

Five minutes work with a 17mm socket and spanner.

This was a fairly bespoke job but I did collect some measurements if anyone is keen enough to have a go. It's fairly apparent what you need to do once you have a kit in front of you.

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please use the contact us link at the bottom of the page.

-

Guest submit your best shot for a chance to win the December Photo Contest. Photo Contest Click Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lifting your truck has to be considered a game of Russian Roulette at this point. No lift is going on my rig. Perfectly happy with the stance on the OEM suspension and 255/85R17 Mickey Thompson tires. I might replace the shocks but they will match the length of the factory units from Sachs.

Last edited:

Lifting your truck just has the potential to accelerate failure, but they will all fail at some mileage.

They will all fail, but I would rather get more mileage out of each CV joint before failure.Lifting your truck just has the potential to accelerate failure, but they will all fail at some mileage.

Understandable, but the cost is minimal over 100k miles. As well I kind of like the reliability of a lifted truck taking out the boot every 7-10k miles. But stock trucks can go 5k or 50k or whenever. As well replacing the joint every 10k gives you a chance to catch a broken clip.They will all fail, but I would rather get more mileage out of each CV joint before failure.

FWIW I strongly suspect that front / rear CV joint failure with stock suspension in place isn’t a P( E )=1 event on reasonable timelines…

Also Agile makes a top notch rear replacement, which if I did a bigger lift I would add. We have all we need, except a front end fix.

The rear shaft is likely good for 100k miles or more. The angles stock or lifted are very conservative out back.Also Agile makes a top notch rear replacement, which if I did a bigger lift I would add. We have all we need, except a front end fix.

Is it 100%, well over what time frame? But without question failure is 100% of course over some period. But being more specific to your point, I personally feel you are being naive about the potential of failure on stock trucks. Sure you are right that the odds may not be quite 100% on a stock truck, but they are high enough to warrant significant concern.FWIW I strongly suspect that front / rear CV joint failure with stock suspension in place isn’t a P( E )=1 event on reasonable timelines…

- Local time

- 5:20 PM

- Joined

- Sep 25, 2021

- Messages

- 570

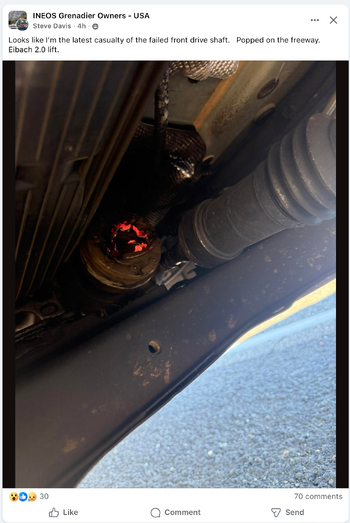

Pending a permanent fix, would periodic (or constant) monitoring of the Transfer Case temperature (on the Offroad display) provide any early warning of a failure such as this?Note mine but posted 4 hours ago on Facebook group by Steve Davis. 2" lift. Melt down for sure.

I will not be lifting my truck.

My personal change interval will be 10K miles. With the stock suspension I would like to think the odds of the CV failing sooner than that will be small. With a lift I would not be confident that I could regularly get 10K miles between change intervals. If the Grenadier were my only rig for all off roading I might feel differently but I have a Jeep Wrangler for technical terrain and rock crawling leaving the Grenadier for moderate terrain and overlanding. Given this the utility of a lift for the Grenadier is minimal.Understandable, but the cost is minimal over 100k miles. As well I kind of like the reliability of a lifted truck taking out the boot every 7-10k miles. But stock trucks can go 5k or 50k or whenever. As well replacing the joint every 10k gives you a chance to catch a broken clip.

If I understand it correctly, the boot problem isn't wear over time ? When it fails , it does so rapidly. So what are you achieving by replacing it regularly. Catch a mission clip is one, but maybe needs more frequent checking than 10k miles.

For people who have had multiple failures, did they happen at about the same sort of milage?

For people who have had multiple failures, did they happen at about the same sort of milage?

The objective is to replace the CV joint before the boot failure happens. It doesn't fail randomly, it fails from accumulated damage which occurs over time. On a stock truck most failures seem to happen after accumulating over 10K miles. On lifted trucks the interval has been under 5K miles in some cases but also over 10K miles as well. Changing the CV at regular intervals as preventative maintenance will minimize the the likely hood of a failure happening while in the field or a remote location. It is always easier to change the CV in the garage with parts and tools at hand and clean conditions as opposed to on your back in the dirt with a minimal tool kit.If I understand it correctly, the boot problem isn't wear over time ? When it fails , it does so rapidly. So what are you achieving by replacing it regularly. Catch a mission clip is one, but maybe needs more frequent checking than 10k miles.

For people who have had multiple failures, did they happen at about the same sort of milage?

If you tow regularly this logic may not apply. There are reports of more instantaneous type failures from loading the hitch while going over undulations or other terrain.

Last edited:

Is this only a rear problem? Agile makes front and rear shafts I believe.

Not say I going to, but I have been thinking about just buying the Agile preemptively. A lot easier to do when there is no damage.

Not say I going to, but I have been thinking about just buying the Agile preemptively. A lot easier to do when there is no damage.

Agile shafts are fine if your primary mission is off-road. Sustained highway speeds with the Agile shafts, especially the front one, introduces harmonics/vibrations which you will feel and will be transmitted into the front differential and t-case which might cause issues down the road.

Donno. Seems crazy that you would need a digital screen up constantly to monitor tcase temp for excessive heat when driving. So much for using CarPlay.Pending a permanent fix, would periodic (or constant) monitoring of the Transfer Case temperature (on the Offroad display) provide any early warning of a failure such as this?

Good question.Pending a permanent fix, would periodic (or constant) monitoring of the Transfer Case temperature (on the Offroad display) provide any early warning of a failure such as this?

The oil temperature probe is fitted at the bottom of the casing on the left side towards the rear. It's quite a way from the front output flange in conductive heat path terms. My opinion is by the time it registered a change in oil temperature due to an overheating CV the CV would be well into meltdown. Because the oil is continuously circulating the whole 2.64 litres of oil would need to heat up to register the change.

When I made my loop mount bracket I left a 4-hole tab so I have somewhere to mount a camera, or a laser thermometer, if I want to observe the CV during operation.

Rear left side of the TC looking forwards. Rear output flange visible.

You will have other warnings well before you see the nuclear reactor start to melt down. Primarily you will feel and hear a harmonic. And of course if you visually and physically inspect your front boot you will catch it even earlier.Pending a permanent fix, would periodic (or constant) monitoring of the Transfer Case temperature (on the Offroad display) provide any early warning of a failure such as this?

There are seemingly some exceptions to this but I suspect a few signs may have been understandably missed or there is a more serious failure mode that is virtually unavoidable and we all have to accept the outcome of the dice we roll. Because I have driven with a torn boot for hundreds of miles and have seen how difficult it can be to catch a tear if you aren't really looking I very much suspect all the melt downs had developed over significant distance or higher than normal loads and all at high speeds.

Use your eyes, but don't be afraid to get your fingers dirty. And after 5k miles you might start checking at every fill up and or daily if you are not at your home base.

Front problem almost exclusively.Is this only a rear problem? Agile makes front and rear shafts I believe.

Not say I going to, but I have been thinking about just buying the Agile preemptively. A lot easier to do when there is no damage.

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 75

- Views

- 5K

- Replies

- 52

- Views

- 2K

- Replies

- 1

- Views

- 200

- Replies

- 2K

- Views

- 93K