I've found what appears to be either conflicting or ambiguous information in the workshop manual regarding the torque specification for the front lower control arm bolt and nut.

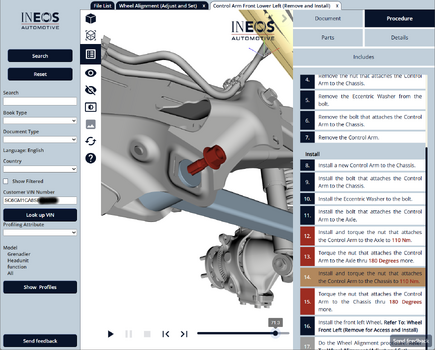

LOWER CONTROL ARM - REMOVE AND REPLACE

The procedure for removing and replacing the front lower control arm is found at

Workshop Manual | Station Wagon and Utility Wagon | 4. Steering and Suspension |

4C. Front Suspension | Control arm Front Lower Left (Remove and Install)

This document includes the following instructions:

14. Install and torque the nut that attaches the Control Arm to the Chassis to 110 Nm.

15. Torque the nut that attaches the Control Arm to the Chassis thru 180 degrees more.

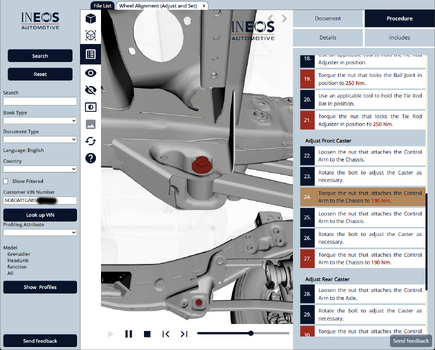

WHEEL ALIGNMENT

The procedure for aligning the front wheels is found at

Workshop Manual | Station Wagon and Utility Wagon | 4. Steering and Suspension |

4B. Steering | Wheel Alignment (Adjust and Set)

This document includes the following instructions:

27. Torque the nut that attaches the Control Arm to the Chassis to 190 Nm.

DISCUSSION

The problem I see here is that the first procedure [110 Nm then 180° more] results in a far higher torque than 190 Nm. I had to use my impact wrench to achieve this spec . . . my WAG is it's in the 350 - 475 Nm range.

The only explanation I can think of is that the spec of [110 Nm then 180° more] might only be intended for the initial construction at the factory. The intent might be to compress the underlying steel structure ONE TIME with this procedure, then for every time thereafter - for the life of the vehicle - that the 190 Nm specification would apply.

I adjusted the caster on my vehicle recently and had only found the remove and replace procedure [110 Nm then 180° more], so my lower control arm fasteners are currently sitting at the amount of stretch resulting from that procedure. The bolt ought to be able to handle this amount of stretch without plastic deformation since the alignment procedure does not say to replace the bolt (a torque to yield bolt would need to be replaced any time the joint was loosened, e.g., during an alignment).

I'm inclined to remove the nut and bolt and inspect (with a micrometer) for necking that might indicate an overtorque condition, and if all is well, replace the fasteners and torque to 190 NM.

Any ideas on what Ineos intended here?

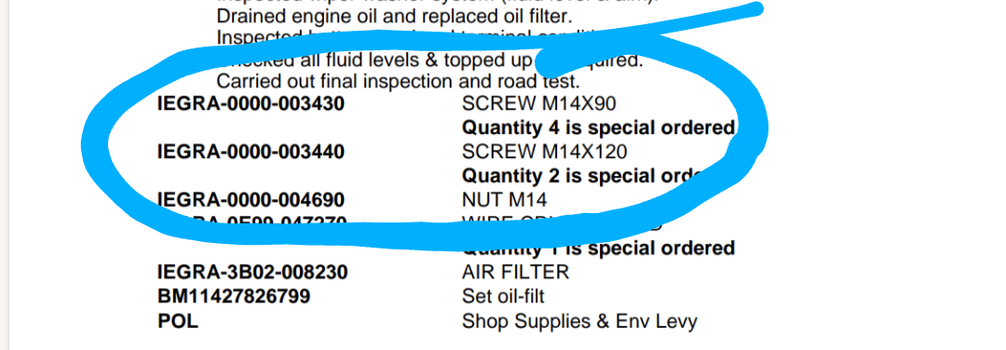

I submitted feedback through the workshop manual site requesting clarification, but have not received a reply after more than two weeks. I also sent an email today to customerservice@ineosgrenadier.com asking with whom I can converse about this subject. I'll update this thread with any replies.

LOWER CONTROL ARM - REMOVE AND REPLACE

The procedure for removing and replacing the front lower control arm is found at

Workshop Manual | Station Wagon and Utility Wagon | 4. Steering and Suspension |

4C. Front Suspension | Control arm Front Lower Left (Remove and Install)

This document includes the following instructions:

14. Install and torque the nut that attaches the Control Arm to the Chassis to 110 Nm.

15. Torque the nut that attaches the Control Arm to the Chassis thru 180 degrees more.

WHEEL ALIGNMENT

The procedure for aligning the front wheels is found at

Workshop Manual | Station Wagon and Utility Wagon | 4. Steering and Suspension |

4B. Steering | Wheel Alignment (Adjust and Set)

This document includes the following instructions:

27. Torque the nut that attaches the Control Arm to the Chassis to 190 Nm.

DISCUSSION

The problem I see here is that the first procedure [110 Nm then 180° more] results in a far higher torque than 190 Nm. I had to use my impact wrench to achieve this spec . . . my WAG is it's in the 350 - 475 Nm range.

The only explanation I can think of is that the spec of [110 Nm then 180° more] might only be intended for the initial construction at the factory. The intent might be to compress the underlying steel structure ONE TIME with this procedure, then for every time thereafter - for the life of the vehicle - that the 190 Nm specification would apply.

I adjusted the caster on my vehicle recently and had only found the remove and replace procedure [110 Nm then 180° more], so my lower control arm fasteners are currently sitting at the amount of stretch resulting from that procedure. The bolt ought to be able to handle this amount of stretch without plastic deformation since the alignment procedure does not say to replace the bolt (a torque to yield bolt would need to be replaced any time the joint was loosened, e.g., during an alignment).

I'm inclined to remove the nut and bolt and inspect (with a micrometer) for necking that might indicate an overtorque condition, and if all is well, replace the fasteners and torque to 190 NM.

Any ideas on what Ineos intended here?

I submitted feedback through the workshop manual site requesting clarification, but have not received a reply after more than two weeks. I also sent an email today to customerservice@ineosgrenadier.com asking with whom I can converse about this subject. I'll update this thread with any replies.

Attachments

Last edited: