I need to check mine after the recent install. I lightly put the clamp on the boot end. In that the metal clamp is tight enough to stay in its groove, but loose enough that I can rotate it by hand.

I wanted it to allow the boot to move and settle where ever it needed over time without being bound at a certain location.

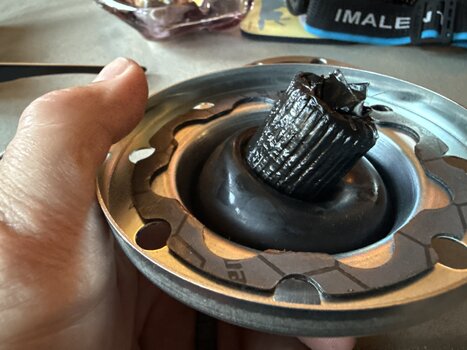

I need to check that no grease has made its way out.

I wanted it to allow the boot to move and settle where ever it needed over time without being bound at a certain location.

I need to check that no grease has made its way out.