We’re currently drying off after rafting in the Tara canyon. Second deepest in the world after the grand canyon.I watched a programme about Montenegro and didn’t realise it’s the second most mountainous country in Europe after Switzerland

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please use the contact us link at the bottom of the page.

-

Guest submit your best shot for a chance to win the December Photo Contest. Photo Contest Click Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do with your Grenadier today?

- Thread starter Stu_Barnes

- Start date

-

- Tags

- grenadier

In North America, Hell's Canyon is recognized as the deepest canyon at 7,993 ft (2,436 m), while the Grand Canyon at 6,093 ft (1,857 m) ranks about 4th or 5th deepest, depending on how each is measured. Other canyons in Tibet, Nepal, Pakistan, and Peru are more than 10,000 ft (3,000 m) deep.

I guess it’s how you measure it and what you class as a canyon.

Yesterday we went on Montenegro’s longest zip line. Then today we were offered a ride on Montenegro’s longest zip line. They are not the same lol.

Yesterday we went on Montenegro’s longest zip line. Then today we were offered a ride on Montenegro’s longest zip line. They are not the same lol.

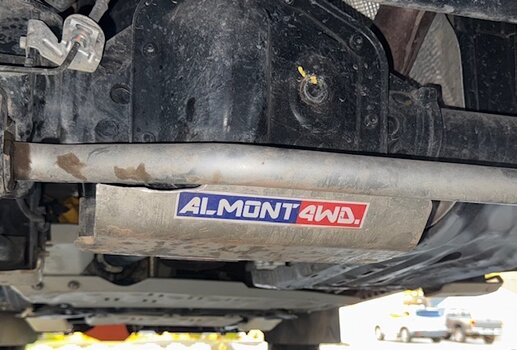

Yes and the rear sway bar . When fully loaded in Morocco I kept hearing a squeak going over bumps and the rear differential guard was rubbing on the bar so had to cut some of that to.If you fit the Almont skid plate, check if it touches the steering rod, because in my case I had to cut about 3 cm

Rear guard before cutting

Front guard after cutting

Not in my grenny, but I flew down to Sydney for the 3 day weekend to watch the last tour match of the British and Irish Lions v Wallabies.

If any of you guys from the British Isles or Ireland were here in Sydney and bumped into me down at the Rocks after the game until the wee hours of the morning, it was great to meet you, I apologize if my enthusiasm for your visit was somewhat energetic, and I’m sorry if my singing voice is still grating at your eardrums this morning. I met a hundred of you last night and you were all gentle men and women to a fault. Even you Jimmy from Thurso Scotland who sprayed single malt scotch all over my face and clothes in a swallow gone wrong.

Great party.

Safe trip home!

If any of you guys from the British Isles or Ireland were here in Sydney and bumped into me down at the Rocks after the game until the wee hours of the morning, it was great to meet you, I apologize if my enthusiasm for your visit was somewhat energetic, and I’m sorry if my singing voice is still grating at your eardrums this morning. I met a hundred of you last night and you were all gentle men and women to a fault. Even you Jimmy from Thurso Scotland who sprayed single malt scotch all over my face and clothes in a swallow gone wrong.

Great party.

Safe trip home!

Not in my grenny, but I flew down to Sydney for the 3 day weekend to watch the last tour match of the British and Irish Lions v Wallabies.

If any of you guys from the British Isles or Ireland were here in Sydney and bumped into me down at the Rocks after the game until the wee hours of the morning, it was great to meet you, I apologize if my enthusiasm for your visit was somewhat energetic, and I’m sorry if my singing voice is still grating at your eardrums this morning. I met a hundred of you last night and you were all gentle men and women to a fault. Even you Jimmy from Thurso Scotland who sprayed single malt scotch all over my face and clothes in a swallow gone wrong.

Great party.

Safe trip home!

The view from higher up. Averaged 14 mpg climbing up there!

Thanks for bringing this up.Yes and the rear sway bar . When fully loaded in Morocco I kept hearing a squeak going over bumps and the rear differential guard was rubbing on the bar so had to cut some of that to.

Rear guard before cutting

View attachment 7903876

Front guard after cutting

View attachment 7903875

I too have had to customize Altmont’s skid plates…do they not have sway bars in Spain?

They also only use cheap bolts (mine snapped on first impact) in the swing arm skid, and single side weld the swing arm skid plate ( see damage). You may want to consider installing higher grade bolts and having your welder weld the back side too if you have the swing arm skid plate.

All straight and fixed (welded inside and out) and new bolts (thanks Custom Machine)

My morning was installing Agile’s adjustable sway bar mounts by Apex. Lots of skid plate cutting for clearance with the Eibach adjustable sway bar. Will evaluate soon. We’re not a go fast/die hard like John (at Agile), but Moab and Colorado will give em’ a work out.

I was considering the same combination. When I spoke with John about it he advised against it as the end links would be easily overpowered by the stiffer bar. I’m interested in your experience and if it’s possible to generate enough pressure to realize the full stiffness of the bar on the street.My morning was installing Agile’s adjustable sway bar mounts by Apex. Lots of skid plate cutting for clearance with the Eibach adjustable sway bar. Will evaluate soon. We’re not a go fast/die hard like John (at Agile), but Moab and Colorado will give em’ a work out.

View attachment 7903958

Stopped at Trona Pinnacles, otherworldly tufa towers in Searles Valley, born from an ancient lake....en route to Mammoth Lakes.

Disclaimer- not an engineer, just a dummy with lots of time tuning race cars-and an active imagination.I was considering the same combination. When I spoke with John about it he advised against it as the end links would be easily overpowered by the stiffer bar. I’m interested in your experience and if it’s possible to generate enough pressure to realize the full stiffness of the bar on the street.

That said,

We should get a city speed idea in the morning and a highway this weekend.

Notable facts:

Truck is usually about 6500lbs, camping weight is 7000lbs at about 40f/60r weight distribution. Koni raids, 500lb rear springs and Eibach rear sway bar. Metal Cloak front disconnects, Full skids, sliders, etc bring the CG down - pizza cutters and a bit less than 300 dynamic lbs on/near the roof bring the CG way back up. The rear bar’s stiffest position is a rate of 272lbs (per Eibach), but don’t know at what amount of flex/displacement. This is apparently double the factory rate.

The Apex’s will go up to 300psi, which, not having a spring gauge or knowing the air volume, or if the stroke end is less than than the total chamber volume, makes it anyone’s guess at what point they will start compressing (stiction+initial rate) and when/if lock out/end stroke happens. The big question for me is how fast will the tiny air spring’s rate ramp-up with a little shock’s small amount of air volume, because, at some point it should become effectively rigid - either no more room, or shock spring rate greater than sway bar spring rate - and push the sway bar normally. I think (hope) it will function, on road, fully loaded as variable rate sway bar, the whole system stiffening at a non linear rate as the lean angle grows. I suspect it won’t be as good (softer) in sharp slalom maneuvers than the current setup, but equal the stock links in long highway curves. Current setup is way better than stock, great on road, but the rear bar is best disconnected off road or removed for serious stuff like Moab.

Having watched John’s YT video, the sway bar usually remains at about the same angle, meaning the whole system is only using the air springs/end links and the bar is effectively rigid (think 962), only on big hits does the air spring seem to ramp-up and then force the sway bar to flex. The shaft’s dirt line seems to indicate where that change is usually happening.

However, My real reason for getting these is exclusively for Off-road. The goal is an easy rear sway bar disconnect (mostly) but with that air spring ramp-up effect engaging the sway bar if things get way crossways out back and to flex the front axle. So if they rock off-road, I’ll keep em even if on road slides back towards stock. If not, you’ll see them in the classifieds.

Thanks @Brandnm. I’ve got new bolts ready for when I get my vehicle back from the dealers. At the moment all guards are off as I I took them off to facilitate warranty works and exhaust mods to fit LRA fuel tank. I found the bolts very soft and struggled with some and one rounded out completely so had to be drilled out to be extracted. I’ve bought two kinds and deciding which to use. I have high tensile and stainless steel replacements. Plus I’ve also cut a small piece off of the transmission guard to make it easier to get my hand and arm in to hold the spanner and nut whilst tightening the bolt with the other hand. I’ve cut a piece off the back left corner of the guard.Thanks for bringing this up.

I too have had to customize Altmont’s skid plates…do they not have sway bars in Spain?

View attachment 7903950

They also only use cheap bolts (mine snapped on first impact) in the swing arm skid, and single side weld the swing arm skid plate ( see damage). You may want to consider installing higher grade bolts and having your welder weld the back side too if you have the swing arm skid plate.

View attachment 7903953View attachment 7903954

All straight and fixed (welded inside and out) and new bolts (thanks Custom Machine)

Last edited:

Filled up my adblue from a service station pump for the first time today. (French supermarket) Quite a bit cheaper and certainly less messy.

Our local service station has just installed an adblue pump. Just waiting for it to commissioned and the price determined.Filled up my adblue from a service station pump for the first time today. (French supermarket) Quite a bit cheaper and certainly less messy.

Finally finished the GMRS install. I cut into the plastic and mounted adapter for my Midland 275 mic. When I'm not using the radio, the mic goes in my Tougher front seat pocket. When in use, I attached my mic to a set up I got from Amazon. The color match is almost spot on and cost less than 15 dollars.

Attachments

This thread always confuses me - "what did you do with" vs. "what did you do to". Anyway couple projects over the past week or so.

First was, I got tired of the seatbelt coming across my neck, yeah, I'm somewhat vertically challenged. Anyway, saw this over on FB, so took a chance.

Front Seatbelt holder for 2015-2023 Ford Mustang

Easy install, sold as a pair. The holes are a bit wider than our headrests, but they fit with a little squeezing or you could dremel out one of the holes a bit. .

Next was to FINALLY install a LensunSolar panel on my hood. Took nearly a month for all the bits and pieces to arrive. I didn't go with their MPPT controller, but installed a CTEK 250SE using at GP Factor bracket. Still need to finalize the wiring, but got the panel mounted. Getting wires through the firewall was a B*#ch. Seems they taped the wires to the grommets on the engine side, so couldn't just "poke" the wires through.

Here are the specs of the solar panel - nothing crazy, but I don't have the roof space to put panels and the hood is wasted space anyway.

Finally, just for fun

First was, I got tired of the seatbelt coming across my neck, yeah, I'm somewhat vertically challenged. Anyway, saw this over on FB, so took a chance.

Front Seatbelt holder for 2015-2023 Ford Mustang

Easy install, sold as a pair. The holes are a bit wider than our headrests, but they fit with a little squeezing or you could dremel out one of the holes a bit. .

Next was to FINALLY install a LensunSolar panel on my hood. Took nearly a month for all the bits and pieces to arrive. I didn't go with their MPPT controller, but installed a CTEK 250SE using at GP Factor bracket. Still need to finalize the wiring, but got the panel mounted. Getting wires through the firewall was a B*#ch. Seems they taped the wires to the grommets on the engine side, so couldn't just "poke" the wires through.

Here are the specs of the solar panel - nothing crazy, but I don't have the roof space to put panels and the hood is wasted space anyway.

Finally, just for fun

Green Gren

Grenadier Owner

My Leitner roof rack came in handy when I had to take (5) 33+” wheels/tires back from the tire shop. Three in back and two on the roof. I switched from 18’s with snow rated Yokohama AT4’s to 17’s with RT Yokohama X-AT’s.

Similar threads

- Replies

- 4

- Views

- 313

- Replies

- 60

- Views

- 2K

- Replies

- 2

- Views

- 443