Agreed it’s pricey. Probably cheaper around or a coach bolt with head ground down on two parallel sides would do the trick also.7 GBP / piece is insane.

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please use the contact us link at the bottom of the page.

-

Guest submit your best shot for a chance to win the December Photo Contest. Photo Contest Click Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Internal platform

- Thread starter grenadierboy

- Start date

Agree - I ordered 4 pieces with a length of 15mm (which should be more than sufficient if not even better for this purpose) for 11,97 EUR at Amazon:Agreed it’s pricey. Probably cheaper around or a coach bolt with head ground down on two parallel sides would do the trick also.

(Fixed typo)

An optimistic 6+ months for NA deliveries to start, and I am paying close attention to this thread. I will install a fridge and not sure how to plan the remaining cargo space. I am frightfully aware of the weigh penalties these wooden system bring, so hopefully a good solution floats above the others.

Fantastic Christoph, thanks so much for the detailed explanation and photos. I want to do something similar and this really helps.

What kind of wood is needed or the best? 3/8 inch, 1/2 inch? 1/4, but use some aluminum brackets/cross members?An optimistic 6+ months for NA deliveries to start, and I am paying close attention to this thread. I will install a fridge and not sure how to plan the remaining cargo space. I am frightfully aware of the weigh penalties these wooden system bring, so hopefully a good solution floats above the others.

I would prefer a substrate other than wood.What kind of wood is needed or the best? 3/8 inch, 1/2 inch? 1/4, but use some aluminum brackets/cross members?

There are very light panels for the interieur available, which are used in the flight industry. Various colours and surfaces...but still being strong.An optimistic 6+ months for NA deliveries to start, and I am paying close attention to this thread. I will install a fridge and not sure how to plan the remaining cargo space. I am frightfully aware of the weigh penalties these wooden system bring, so hopefully a good solution floats above the others.

Like Con-Pearl. Together with appropriate profiles you can easil, get any kind of case. There was once a company called 4x4innenausbau who offered ready Excel sheets for standard cases and the usual cars which come together as complete furniture. You just needed to measure and put the numbers in. You received from Excel a complete order list and construction manual.

Or you ask Lynn, she was in the compound business before...

AWo

Yes, composites might be great for a rear drawer system for weight however may be more fussy to fab with. I am thinking of using 3/8" or 1/2" birch plywood vs regular plywood for strength. My thoughts on a rear drawer and tray system is to break it up into two separate drawer/tray boxes, side by side. It would be much lighter to take them in and out and also gives you the option of just putting one set in and having a refrigerator next to it or installing both sets to have a full width set up. Much more flexibility. This is the way I am going to go along with engineering a top on top of each set that will be on commercial grade Accuride guide/slides to allow the top to slide back and forth. I have not worked out all the details yet and when I do will post photos and details. DaBull.There are very light panels for the interieur available, which are used in the flight industry. Various colours and surfaces...but still being strong.

Like Con-Pearl. Together with appropriate profiles you can easil, get any kind of case. There was once a company called 4x4innenausbau who offered ready Excel sheets for standard cases and the usual cars which come together as complete furniture. You just needed to measure and put the numbers in. You received from Excel a complete order list and construction manual.

Or you ask Lynn, she was in the compound business before...

AWo

I have a lot of time. In about a year I could TIG a frame and mount to the cargo aircraft rails. Easy to attach the fridge slide and I can hopefully plan out the rest of the storage.Yes, composites might be great for a rear drawer system for weight however may be more fussy to fab with. I am thinking of using 3/8" or 1/2" birch plywood vs regular plywood for strength. My thoughts on a rear drawer and tray system is to break it up into two separate drawer/tray boxes, side by side. It would be much lighter to take them in and out and also gives you the option of just putting one set in and having a refrigerator next to it or installing both sets to have a full width set up. Much more flexibility. This is the way I am going to go along with engineering a top on top of each set that will be on commercial grade Accuride guide/slides to allow the top to slide back and forth. I have not worked out all the details yet and when I do will post photos and details. DaBull.

wood/foam/wood sandwiches are very lightweight and strong.

But apart from the higher cost, they also have some disadvantages.

The first is the connection of the panels. While metal panels can be welded, screwed or riveted, and wood can simply be glued, doweled, nailed or screwed, this is a bit more challenging with sandwich panels.

The second issue is force application. Such a panel is strong as a planar member and can support a lot of load. But point loads can be critical. The same is true for any connections that need to be made, whether between multiple panels or even between fittings.

In short, workmanship is more demanding and less forgiving. Specialty adhesives can help, but they are expensive and often have a limited working time with 2K adhesives. There can be special fittings that solve such problems, but the prices are usually beyond.

Wood is a patient, (comparatively) inexpensive and easy to work with material. It takes some effort to make it resistant to water, grease and sweat. But it is (at least for me) a pleasure to work with. And wherever you need a handle or other piece of wood, you just take a screw and you're done.

The trick is in the sizing and construction. Most vertical structures are fine with 9 mm thickness. Horizontal structures are often strong enough at 12 mm, and in drawers even 9 mm or 5 mm can be enough. 19 mm is almost never necessary.

With additional design measures, even a horizontal bed can be built with 12 mm. It depends very much on the imagination, skill and patience of the builder.

The nice thing with wood is that you can easily scale it down to almost any requirements and space restrictions.

Imagine the beam below at a height of 50 mm. It takes a fretsaw or a handrouter - and time. The strength is just incredible.

I once built an RC controlled airplane from wood. It had a wing span of 139 cm, had a battery, two servos, an RC-receiver with antenna and all the linkages for the rudder and ailerons. It weighed 99 grams.

Here is a nice website which visualizes the principles of wooden lightweight constructions (although this is for much larger loads).

typo

But apart from the higher cost, they also have some disadvantages.

The first is the connection of the panels. While metal panels can be welded, screwed or riveted, and wood can simply be glued, doweled, nailed or screwed, this is a bit more challenging with sandwich panels.

The second issue is force application. Such a panel is strong as a planar member and can support a lot of load. But point loads can be critical. The same is true for any connections that need to be made, whether between multiple panels or even between fittings.

In short, workmanship is more demanding and less forgiving. Specialty adhesives can help, but they are expensive and often have a limited working time with 2K adhesives. There can be special fittings that solve such problems, but the prices are usually beyond.

Wood is a patient, (comparatively) inexpensive and easy to work with material. It takes some effort to make it resistant to water, grease and sweat. But it is (at least for me) a pleasure to work with. And wherever you need a handle or other piece of wood, you just take a screw and you're done.

The trick is in the sizing and construction. Most vertical structures are fine with 9 mm thickness. Horizontal structures are often strong enough at 12 mm, and in drawers even 9 mm or 5 mm can be enough. 19 mm is almost never necessary.

With additional design measures, even a horizontal bed can be built with 12 mm. It depends very much on the imagination, skill and patience of the builder.

The nice thing with wood is that you can easily scale it down to almost any requirements and space restrictions.

Imagine the beam below at a height of 50 mm. It takes a fretsaw or a handrouter - and time. The strength is just incredible.

I once built an RC controlled airplane from wood. It had a wing span of 139 cm, had a battery, two servos, an RC-receiver with antenna and all the linkages for the rudder and ailerons. It weighed 99 grams.

Here is a nice website which visualizes the principles of wooden lightweight constructions (although this is for much larger loads).

Holzleichtbau - Ingenieurbüro Albrecht Löser

Leichter bauen und zugleich die Produktivität erhöhen

www.albrechtloeser.de

typo

Last edited:

Hi Christoph, I like your tray set up instead of drawers. Easy to simply pull out and stack and put back in.OK, here we go:

The reason for the shorter bottom board (84 cm instead of 90 cm top board) is this form of the trunk floor:

View attachment 7817273

The rear of the box, thus, looks like this:

View attachment 7817278

View attachment 7817279

View attachment 7817280

And regarding securing the box to the floor, as I said above, I have done nothing yet, but was thinking that the air rails could be leveraged for this purpose as the box fits perfectly between them:

View attachment 7817281View attachment 7817282

In looking at your measurements, it appears that the depth of the two trays, 60cm + 30cm = 90cm, exceeds the depth of the bottom board, that you showed as being 82cm or perhaps could be 84cm. Is the bottom board deeper than 82-84cm and if so, what is that measurement?

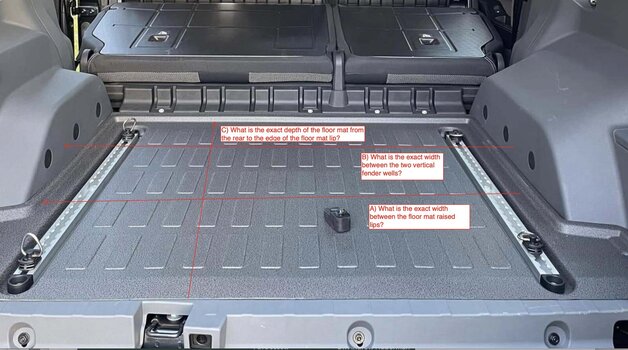

I am thinking of making something similar to yours, however going full width past the airline rails up to, however not over, the small floor mat lip to the right and left of the airline rails. If you have the time, could you take the exact measurements for A, B & C as shown on the attached photo. Thanks in Advance. DaBull

Attachments

Last edited:

Hi DaBull,

Yes.

It is not, the boxes go beyond the bottom board.

Sure, here you go:

A: 102.0 cm (40.16 inches)

B: 106.8 cm (42.05 inches)

C: 84.2 cm (33.15 inches)

In looking at your measurements, it appears that the depth of the two trays, 60cm + 30cm = 90cm, exceeds the depth of the bottom board,

Yes.

that you showed as being 82cm or perhaps could be 84cm. Is the bottom board deeper than 82-84cm and if so, what is that measurement?

It is not, the boxes go beyond the bottom board.

I am thinking of making something similar to yours, however going full width past the airline rails up to, however not over, the small floor mat lip to the right and left of the airline rails. If you have the time, could you take the exact measurements for A, B & C as shown on the attached photo. Thanks in Advance. DaBull

Sure, here you go:

A: 102.0 cm (40.16 inches)

B: 106.8 cm (42.05 inches)

C: 84.2 cm (33.15 inches)

Just realized I should add that I have a Stationwagon Trialmaster spec - the utility version has different measures due to the rear seats being installed differently.Hi DaBull,

Yes.

It is not, the boxes go beyond the bottom board.

Sure, here you go:

A: 102.0 cm (40.16 inches)

B: 106.8 cm (42.05 inches)

C: 84.2 cm (33.15 inches)

Hi Christoph, Thanks for the great information. Much appreciate. DaBullJust realized I should add that I have a Stationwagon Trialmaster spec - the utility version has different measures due to the rear seats being installed differently.

Does anyone know how the upper lashing eyes in the load compartment are attached and how much weight they can support? If you unscrew them, you can see a hollow space behind the metal eyelet that holds them. Could the mounting for a false floor be anchored here?

I have the same question about the linkage that moves the partition forward 10 cm in the 5-seater Utility Wagon. Could this serve as an anchorage for a small winch in the load compartment? Pulling force approx. 100 - 150 kg.

Weren't there pictures of the raw bodywork somewhere?

Many thanks for any help or ideas on these subjects.

--

Weiß jemand, wie die oberen Verzurrösen im Laderaum angebracht sind und wieviel Gewicht sie tragen können? Wenn man sie abschraubt, ist hinter der sie haltenden Metallöse ein Hohlraum zu sehen. Evtl. könnte man hier die Halterung für einen Zwischenboden verankern?

Die gleiche Frage hätte ich zu dem Gestänge, das die Trennwand im 5-Sitzer Utility Wagon 10 cm nach vorne verlagert. Könnte das als Verankerung für einer kleine Seilwinde im Laderaum dienen? Zugkraft ca. 100 – 150 kg.

Gab es nicht mal irgendwo Bilder von der rohen Karosserie?

Vielen Dank für jede Hilfe oder Idee zu diesen Themen.

I have the same question about the linkage that moves the partition forward 10 cm in the 5-seater Utility Wagon. Could this serve as an anchorage for a small winch in the load compartment? Pulling force approx. 100 - 150 kg.

Weren't there pictures of the raw bodywork somewhere?

Many thanks for any help or ideas on these subjects.

--

Weiß jemand, wie die oberen Verzurrösen im Laderaum angebracht sind und wieviel Gewicht sie tragen können? Wenn man sie abschraubt, ist hinter der sie haltenden Metallöse ein Hohlraum zu sehen. Evtl. könnte man hier die Halterung für einen Zwischenboden verankern?

Die gleiche Frage hätte ich zu dem Gestänge, das die Trennwand im 5-Sitzer Utility Wagon 10 cm nach vorne verlagert. Könnte das als Verankerung für einer kleine Seilwinde im Laderaum dienen? Zugkraft ca. 100 – 150 kg.

Gab es nicht mal irgendwo Bilder von der rohen Karosserie?

Vielen Dank für jede Hilfe oder Idee zu diesen Themen.

Some great stuff here. Don't hesitate to build with plywood. I copied an aluminium draw set in ply and it was lighter and strong enough to do some very serious off-roading over more than 10 years. Screw, glue and rebate is extremely strong. 9mm and 12mm is all that is needed.

Can anyone confirm that the to-seat version truly has a flat floor? And if so, here does the battery and fuses etc. go?

Hi Greg and community,no drawings as i don't have sizes yet, but...

about 500mm at base wide to fit 30l drawer fridge - the top is wider (250 - 300mm?) to extend over the horrible wheel arch -

about 900mm long as the floor length is apparently 980 behind rear seats (38.7 inches) but taking into account the angle of the back seat i am hopping that i can fit 900mm

about 450 high - need to fit fridge 250mm plus slide out tables, and the height of that wheel arch cover

with the frame made out of 3030 aluminium extrusion should allow for ease of bolting on and removing the front section over the rear seat

View attachment 7792526

A very rough sketch which hopefully gives you an idea of what i am thinking

View attachment 7792524

and here is just one of many slide out table designs that i am hoping to utilise. this one has extendable legs to supportView attachment 7792525

What is the true height of the rear seat when folded? I also would like to install some shelf and drawer system. I have seen numbers of 175-200 mm, that’s not a great measurement margin but I can fill it in with a bit of cushioning, like my towel. I like to sleep in my vehicle when weekend camping. Thank you.

Similar threads

- Replies

- 8

- Views

- 1K