Interesting, that’s what I thought too. I test drove a 2026 and didn’t notice anything different with the controls to suggest dual zone. Here’s a screenshot of the website. I lay see a single zone control in the pic…It has always been single zone. If it is now dual zone for 2026 that is an update.

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please use the contact us link at the bottom of the page.

-

Guest submit your best shot for a chance to win the December Photo Contest. Photo Contest Click Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model Year 2026 (MY26) – Confirmed & Speculated Changes

- Thread starter Random-Grenadier

- Start date

-

- Tags

- my26

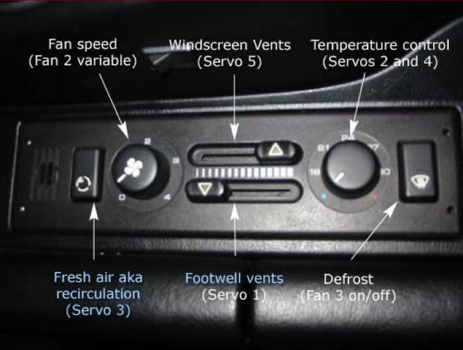

A change to dual zone seems highly unlikely. That would require changes that have not been documented by anyone at this point. The update is almost certainly a change to the current single zone system.Interesting, that’s what I thought too. I test drove a 2026 and didn’t notice anything different with the controls to suggest dual zone. Here’s a screenshot of the website. I lay see a single zone control in the pic…

My ‘24 actually has a 6 zone system. Each of the four dash vents, the floor vent, and rear vents produce different temperatures of air at all times. Sadly, it’s not a joke.Interesting, that’s what I thought too. I test drove a 2026 and didn’t notice anything different with the controls to suggest dual zone. Here’s a screenshot of the website. I lay see a single zone control in the pic…

lol Ineos getting really ambitious.Interesting, that’s what I thought too. I test drove a 2026 and didn’t notice anything different with the controls to suggest dual zone. Here’s a screenshot of the website. I lay see a single zone control in the pic…

They going from 2 zone (cold front / hot back) to 3 zone hvac system?

That’s the advanced Continuously Variable Climate Differention drive at workMy ‘24 actually has a 6 zone system. Each of the four dash vents, the floor vent, and rear vents produce different temperatures of air at all times. Sadly, it’s not a joke.

I am fortunate to be one of the lucky owners to not experience much in the way of HVAC gremlins. It is clunky to be sure but it generally heats and cools the cabin without drama. Not quickly, but it gets the job done if left on auto and with the temp adjusted to preference. If only we had a better understanding of why the system doesn't work on so many rigs. Unfortunately Ineos is never going to elucidate us in that regard.

I think there was an error in the marketing when auto spell check corrected to HVAC, should have read HAVOC

Based on how mine is working after 29,000 miles, I would say there is still air in the ones that aren't giving warm air when not on full heat.I am fortunate to be one of the lucky owners to not experience much in the way of HVAC gremlins. It is clunky to be sure but it generally heats and cools the cabin without drama. Not quickly, but it gets the job done if left on auto and with the temp adjusted to preference. If only we had a better understanding of why the system doesn't work on so many rigs. Unfortunately Ineos is never going to elucidate us in that regard.

The other issue is if running full heat for sometime it does mess up tje sensor no matter how cool it is. I find it need to blow full cold air for a while and then set warm, not full on hot and wait for it work and then leave alone.

I am restoring an old Porsche 964 and have been sorting out the HVAC. It just occurred to me that it could be the prototype for the Grenadier design... 3 fans and 5 servos to control the air flow and temperature. To make it even more complicated it has these vents that work off pressure differentials so you get hot or cold depending on which system has more pressure...

Attachments

So my drive today was well ehhh... Drives the same too me at highway speeds but I did notice parking lot was faster response and slightly slightly better turn in... However not as good as mine with the FOX adjustable and turning in my stops.... Overall I'd say it is a no go for me on the ADAS mirror, I don't like it at all. Also highly doubt there will be option for wolfbox without constant codes being thrown. But to each their own I guess. If I was looking for one I'd hunt a 24 or 25 and call it a day.

Yep, those 911 SC and 80's 911 Carreras had HVAC controls that could easily be set to work against each other lol!I am restoring an old Porsche 964 and have been sorting out the HVAC. It just occurred to me that it could be the prototype for the Grenadier design... 3 fans and 5 servos to control the air flow and temperature. To make it even more complicated it has these vents that work off pressure differentials so you get hot or cold depending on which system has more pressure...

did they fix the fuel door to ensure it’s not crooked relative to the adjacent body panels?So my drive today was well ehhh... Drives the same too me at highway speeds but I did notice parking lot was faster response and slightly slightly better turn in... However not as good as mine with the FOX adjustable and turning in my stops.... Overall I'd say it is a no go for me on the ADAS mirror, I don't like it at all. Also highly doubt there will be option for wolfbox without constant codes being thrown. But to each their own I guess. If I was looking for one I'd hunt a 24 or 25 and call it a day.

I know these aftermarket lights....but you gave one answer already yourself. These are aftermarket lights.I never knew all this time that lighting was your bag. Have you looked at the JW Speaker or Oracle Lighting Oculus aftermarket options for the Jeep Wrangler? Can you think of any reason Ineos wouldn’t use something like that for a heated headlamp? I know those models aren’t compatible - I’m just wondering whether they could commission something LIKE that. I agree with you on the temp range - it’s when the snow is “sticky” that you get the buildup. Only at warmer temps. Fortunately or unfortunately, out here it’s been colder than a witch’s *** for the last couple of weeks, so that hasn’t been a problem

What does that mean?

Being a Tier 1 supplier for the OEM (car manufacturer) is a complete different business than pumping some lights into the aftermarket. Other volumes, other responsibilities, other supply chains, other processes etc. Just think about the 10 years obligation to provide spare parts. That goes down to the Tier 2 suppliers, which must keep tools etc. for the requested amount of time. So the Tier 1 supplier needs to have an according relationship to the Tier 2 supplier.

Let's give an example: Many light companies for the aftermarket use Chinese manufactures. Take brands like STRANDS (Sweden), Valostore Purelux (Finland) or even Hella for their aftermarket division. You find the same lights between all of them under different brands, sometimes exactly the same, sometimes slighlty different (same story for the Inoes lightbar, BTW). These brands buy at the same manufactuer and just put their label on. Typically for aftermarket products is that design and function changes very often. That is fine, because it is for the aftermarket and you have to attract the customer. That also means, that the manufacturer constantly changes tooling and the parts they source, software in the devices etc. Such a manufacturer might not be able to provide what a OEM Tier 1 supplier requires over many years.

You have to make sure, that the Tier 2 supplier goes along with you to provide parts for the required amount of time, that they keep the tooling, the electronics, that they can stick to the specifications etc. Tolerances for automotive electronics is very, very tight if you deliver to the OEM, which adds on the price and which requires processes to guarantee that the tolerances are always met. Often chipsets are kept together by daily charge sets to meet the tolerances and you need the processes for that in your manufacturing process, as well. That does not apply to the aftermarket.

You also need processes which know how just-in-time works. You need to establish a logistics chain. That is something different than putting lights into a cupboard and sell them to aftermarket customers. From the OEM side, other requirements exist in quality, lifetime, etc. Nolden lights are tested to live at least 30.000 hours. Actually we see the first Nolden headlights crossing this time line, as they reached the market more than 15 years ago. Still working and still an absolutely 100% clear glass. Aftermarket lights typically have a much shorter guaranteed lifetime (however, I do not know which lifetime JW Speaker etc. offer).

As an OEM Tier 1 supplier you are integrated into the integration, homologation and testing process. You need personnel which can deal with that. You need to know how to document your work and integration for the officials, that also requires personnel with knowledge about that.

In other words an OEM can not go to a pure aftermarket company and grab some lights of the shelf, for reasons given.

What I do know is, that I saw 7" headlights from an US aftermarket manufacturer, which were unusable after 4-5 years. The polycarbonate glass is one of these quality indicators. The glasses of the headlights I saw have become green and there were many small cracks oll over the glass. High quality polycarbonate and a high quality and rigid UV protection coating are very important. Polycarbonate tends to yellowing due to UV light (sun) and minerals (dust, dirt). (BTW, that is one reason why you should NOT polish your polycarbonate headlights. You remove the coating and a few years ago you can throw your lights into the rubbish).

Another quality indictor is the housing. Especially in countries were no salt is used during winter times the aftermarket manufacturers tend to use a not so rigid coating. You often see housing problems with lights from the US, South Africa and Australia. They simply do not face the environment there whcih they face in many European countries, and hey,, it is aftermarket.....Nolden, as a pure Tier 1 supplier, for example, uses a double protection coating system which keeps their housings fine over the whole time and many, many winters. That is also important for an OEM, which sells cars in Europe and all over the world.

And there are other indicators you can not see. You only know about them when you know how these lights are produced.

BTW, I do not know that for JW Speaker, but Osram and Hella do both, aftemarket and Tier 1 supplier. Nolden is a pure Tier 1 supplier, Anrui seems also to be both. They have bought Wipac for example, which provided lights for car manufacturers and aftermarket.

AWo

Last edited:

Are you aware of any OEM that offers heated headlights, or just headlight wash with heated fluid?I know these aftermarket lights....but you gave one answer already yourself. These are aftermarket lights.

What does that mean?

Being a Tier 1 supplier for the OEM (car manufacturer) is a complete different business than pumping some lights into the aftermarket. Other volumes, other responsibilities, other supply chains, other processes etc. Just think about the 10 years obligation to provide spare parts. That goes down to the Tier 2 suppliers, which must keep tools etc. for the requested amount of time. So the Tier 1 supplier needs to have an according relationship to the Tier 2 supplier.

Let's give an example: Many light companies for the aftermarket use Chinese manufactures. Take brands like STRANDS (Sweden), Valostore Purelux (Finland) or even Hella for their aftermarket division. You find the same lights between all of them under different brands, sometimes exactly the same, sometimes slighlty different (same story for the Inoes lightbar, BTW). These brands buy at the same manufactuer and just put their label on. Typically for aftermarket products is that design and function changes very often. That is fine, because it is for the aftermarket and you have to attract the customer. That also means, that the manufacturer constantly changes tooling and the parts they source, software in the devices etc. Such a manufacturer might not be able to provide what a OEM Tier 1 supplier requires over many years.

You have to make sure, that the Tier 2 supplier goes along with you to provide parts for the required amount of time, that they keep the tooling, the electronics, that they can stick to the specifications etc. Tolerances for automotive electronics is very, very tight if you deliver to the OEM, which adds on the price and which requires processes to guarantee that the tolerances are always met. Often chipsets are kept together by daily charge sets to meet the tolerances and you need the processes for that in your manufacturing process, as well. That does not apply to the aftermarket.

You also need processes which know how just-in-time works. You need to establish a logistics chain. That is something different than putting lights into a cupboard and sell them to aftermarket customers. From the OEM side, other requirements exist in quality, lifetime, etc. Nolden lights are tested to live at least 30.000 hours. Actually we see the first Nolden headlights crossing this time line, as they reached the market more than 15 years ago. Still working and still an absolutely 100% clear glass. Aftermarket lights typically have a much shorter guaranteed lifetime (however, I do not know which lifetime JW Speaker etc. offer).

As an OEM Tier 1 supplier you are integrated into the integration, homologation and testing process. You need personnel which can deal with that. You need to know how to document your work and integration for the officials, that also requires personnel with knowledge about that.

In other words an OEM can not go to a pure aftermarket company and grab some lights of the shelf, for reasons given.

What I do know is, that I saw 7" headlights from an US aftermarket manufacturer, which were unusable after 4-5 years. The polycarbonate glass is one of these quality indicators. The glasses of the headlights I saw have become green and there were many small cracks oll over the glass. High quality polycarbonate and a high quality and rigid UV protection coating are very important. Polycarbonate tends to yellowing due to UV light (sun) and minerals (dust, dirt). (BTW, that is one reason why you should NOT polish your polycarbonate headlights. You remove the coating and a few years ago you can throw your lights into the rubbish).

Another quality indictor is the housing. Especially in countries were no salt is used during winter times the manufacturers tends to use a not so rigid coating. Especially US companies are often not so "interested" in requirements of other countries and regions (I see that often with Garmin products and I worked with Novell Netware products (the former worldwide #1 network software provide) and I remember that they never reacted to the market realities which caused problems for us again and again.). Nolden for example uses a double protection coating system which keeps their housing over the whole time and many, many winters. That is also important for an OEM, which sells cars in Europe and all over the world.

And there are other indicators you can not see. You only know about them when you know how these lights are produced.

AWo

I know two, but these lights are "secondary lights" for snow plows. Secondary lights are allowed when your tool hide the main headlights, like it is the case for snow plows. Some people use these lighst to integrate them into their truck bumper to replace the original halogen lights.

Nothing which would fit into something like a grenadier. At least in Europe you would get in trouble if you manufacture you own bracket system to integrate that into your wing due to pedestrian protection rules. You'll loose the operation permit for your car if you do so as you violate the homologation.

That is not a problem for trucks (what my main business is) as pedestrian protection rules only apply to M1 (passenger cars up to 3,5 t) and N1 (commercial cars up to 3,5t). From 3,5 t and above (M1 > 3,5 t) and N2, N3 you do not have pedestrian protection regulations.

AWo

Nothing which would fit into something like a grenadier. At least in Europe you would get in trouble if you manufacture you own bracket system to integrate that into your wing due to pedestrian protection rules. You'll loose the operation permit for your car if you do so as you violate the homologation.

That is not a problem for trucks (what my main business is) as pedestrian protection rules only apply to M1 (passenger cars up to 3,5 t) and N1 (commercial cars up to 3,5t). From 3,5 t and above (M1 > 3,5 t) and N2, N3 you do not have pedestrian protection regulations.

AWo

Are you aware of any OEM that offers heated headlights, or just headlight wash with heated fluid?

THAT’S IT!!!! Exactly what I was looking for.

I’m generally a (small) city dweller and have no experience in off-roading, but I am an auto enthusiast (sports cars). The Grenadier really interests me and my English wife. When I showed her a review video, she really showed a keen interest in the wagon, especially the flag on the side. We typically drive comfy vehicles (Lexus RX and LX), but are open to the Grenadier and less comfort and its quirks. I would like to learn about the off roading hobby and attend some events to learn. The dealership is about 80-90 min away in Atl.

I may take a flogging for asking this question. Would we be able to use (MY 2026) this a daily driver? It will spend 99% of its life on pavement. I have watched most of the reviewer videos, perused over this forum and have read about some major disasters about the earlier models. Some new MY 2025 are now coming with ~$15k off.

Are the MY 2026 changes worth the extra cost?

BTY, I have scheduled a test drive tomorrow.

I may take a flogging for asking this question. Would we be able to use (MY 2026) this a daily driver? It will spend 99% of its life on pavement. I have watched most of the reviewer videos, perused over this forum and have read about some major disasters about the earlier models. Some new MY 2025 are now coming with ~$15k off.

Are the MY 2026 changes worth the extra cost?

BTY, I have scheduled a test drive tomorrow.

Interesting - the fact that nobody offers these as primary OEM. There must be some mystical factor that precludes it which I don’t understand. I guess with the washer option, you can just offer one headlight and then make the washer part of the “cold climate package,” along with heated steering wheel etc. Anyhow, got a heat wave coming this weekend - should hit 22F. Time to break out the Crocs and cargo shorts and show off these white, white man legs. Making America Great Again. Still too cold for snow sticking to the headlights - and I’ll just keep washing the headlights the old fashioned way.I know two, but these lights are "secondary lights" for snow plows. Secondary lights are allowed when your tool hide the main headlights, like it is the case for snow plows. Some people use these lighst to integrate them into their truck bumper to replace the original halogen lights.

Nothing which would fit into something like a grenadier. At least in Europe you would get in trouble if you manufacture you own bracket system to integrate that into your wing due to pedestrian protection rules. You'll loose the operation permit for your car if you do so as you violate the homologation.

That is not a problem for trucks (what my main business is) as pedestrian protection rules only apply to M1 (passenger cars up to 3,5 t) and N1 (commercial cars up to 3,5t). From 3,5 t and above (M1 > 3,5 t) and N2, N3 you do not have pedestrian protection regulations.

AWo

I have a 2023 model, bought 10 months old with 4,500 miles on it. I hit 29,000 yesterday. I have probably done 5 miles off road, but do plan to do more, it's finding the time. So, yes, it can be used as an everyday vehicle. I came from a Freelander 2 which I did use off road a lot more. I have had most of the early issues but they are all fixable. I do believe that even the HVAC is fixable if all the air is out the system. I would say mine is now ok but is took until over 20,000 miles of use to clear all the air out.I’m generally a (small) city dweller and have no experience in off-roading, but I am an auto enthusiast (sports cars). The Grenadier really interests me and my English wife. When I showed her a review video, she really showed a keen interest in the wagon, especially the flag on the side. We typically drive comfy vehicles (Lexus RX and LX), but are open to the Grenadier and less comfort and its quirks. I would like to learn about the off roading hobby and attend some events to learn. The dealership is about 80-90 min away in Atl.

I may take a flogging for asking this question. Would we be able to use (MY 2026) this a daily driver? It will spend 99% of its life on pavement. I have watched most of the reviewer videos, perused over this forum and have read about some major disasters about the earlier models. Some new MY 2025 are now coming with ~$15k off.

Are the MY 2026 changes worth the extra cost?

BTY, I have scheduled a test drive tomorrow.